|

The telescope as seen from below.

|

Subaru has been

able to make these discoveries by making use of cutting-edge technology.

What does this technology involve?

The larger the

aperture (width) of a telescope, the better it can see dim objects.

But when a mirror becomes bigger, it also becomes heavier. It

is easy for a heavy mirror to become warped by just a slight change

in temperature. It also becomes more difficult to make the surface

of the mirror precise by polishing it, and the base that supports

the mirror must be very large.

|

The giant mirror.

|

Subaru uses a

special kind of glass that can withstand changes in temperature.

This glass is 20 centimeters (about 8 inches) thick, much thinner

than anything that has been made for previous telescopes. The

primary mirror was made by a U.S. company and took more than three

and a half years to complete. Even a very small irregularity would

prevent the light captured from a star from properly focusing,

giving a distorted image. In order to prevent this from happening,

a laser was used to check the surface of the mirror many times

in the final stage of production. Finally, engineers used the

very finest grade of a special kind of powder to polish the surface

of the mirror by hand. The stress involved in this work was so

great that some staff members of Japan's National Astronomical

Observatory, which watched over the work of polishing the mirror,

were hospitalized after developing stomach ulcers.

|

The actuators that maintain the mirror's integrity.

|

But Subaru depends

on more than just its mirror. Japanese companies like Sony, Fujitsu,

Hamamatsu Photonics, and famous makers of optical equipment Canon

and Nikon played a role in the development of the instruments

that record and analyze the data that is gathered with the mirror.

One of the revolutionary

technologies that was used in making Subaru is the use of devices

known as actuators to support the primary mirror. Mitsubishi Electric

developed a structure in which the giant mirror is supported by

261 actuators from beneath. One of the most difficult problems

that arose in the construction of Subaru was how to control a

mirror with a diameter of 8.2 meters. Due to concerns about the

weight and precision of mirrors, it had been thought until recently

that the mirror at the Palomar Observatory, which has a diameter

of 5 meters (about 16 feet), was the largest that could be built.

Mirrors built in the past required a thickness in proportion to

their diameter; the wider the mirror, the thicker it had to be.

An 8.2-meter mirror would weigh well over 100 tons if it were

built this way. In fact, Subaru's primary mirror is 20 centimeters

thick and weighs only 23 tons. But because of its remarkable thinness,

this mirror would change shape slightly under its own weight when

it was moved, so engineers came up with the idea of a system of

261 movable actuators that would constantly analyze the weight

they support and make adjustments to correct for any warp that

develops. By doing this, the mirror's surface error was held below

0.1 micron (0.00001 millimeters). Making the world's largest mirror

usable required the application of new technology and the hard

work of a team of engineers.

|

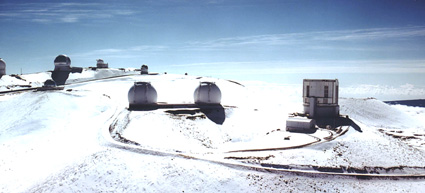

Telescopes from all over the world on the snow-covered peak of Mauna Kea.

|

The location

that was chosen for Subaru was the top of Mt. Mauna Kea in Hawaii,

an ideal place for observing the cosmos. Mauna Kea is 4,205 meters

(about 2.6 miles) above sea-level, and the air is clean and dry.

At night the area is very dark, making it easy to observe the

stars. The weather is clear more than 60% of the time, so there

are about 260 days a year that can be used for observations.

At the top of

the mountain, however, the wind speed averages 7.5 meters per

second, which can affect the temperature in the dome that houses

the telescope and distort the face of the mirror. Images of the

stars are sometimes even blurred by the shaking caused by the

wind.

Many different

ideas were thought up to counter this problem. One was to protect

the dome itself from the wind by making it in the shape of an

ellipse. Another was to install a wind-breaking screen at the

opening through which light enters the telescope. Subaru truly

brings together all kinds of cutting-edge technology.

Photos: National Astronomical Observatory of Japan

|